If you’re noticing loss of suction at the hose end while your vacuum seems fine at the base, don’t rush to blame the motor just yet. Most of the time, this frustrating problem comes down to simple, fixable issues lurking in the hose or attachments. In fact, weak suction at the hose end is usually a sign of clogs, leaks, or filter troubles—not an expensive motor failure. Stick around, because before you consider costly repairs, I’ll walk you through 4 essential checks that will help you pinpoint the real cause and get your vacuum sucking strong again—quickly and easily.

Why Suction Loss Happens at the Hose End

If you notice weak suction at the hose end but strong pull directly at the vacuum body, you’re dealing with a common problem. This kind of suction loss often happens specifically at the hose or attachments, not the main unit or floor head.

Here’s why:

| Vacuum Part | Suction Role | Typical Issue When Weak Suction Occurs |

|---|---|---|

| Hose & Attachments | Carry air from floor tools to vacuum body | Clogs, leaks, or blockages cause suction loss |

| Floor Head/Main Unit | Generate suction and hold motor/filters | Usually fine if suction is strong at body |

You may find that tools like crevice nozzles or upholstery brushes feel weak, but the vacuum still pulls powerfully at the hose connection on the body. This difference tells you the problem is somewhere between hose and tool.

No matter what vacuum type you use—upright, canister, or stick—hose-related suction issues are universal. All rely on clear air pathways through hoses and attachments, so any snag will reduce performance at the tool end.

Remember: Don’t panic — this “vacuum hose no suction” problem is often easy to diagnose and fix!

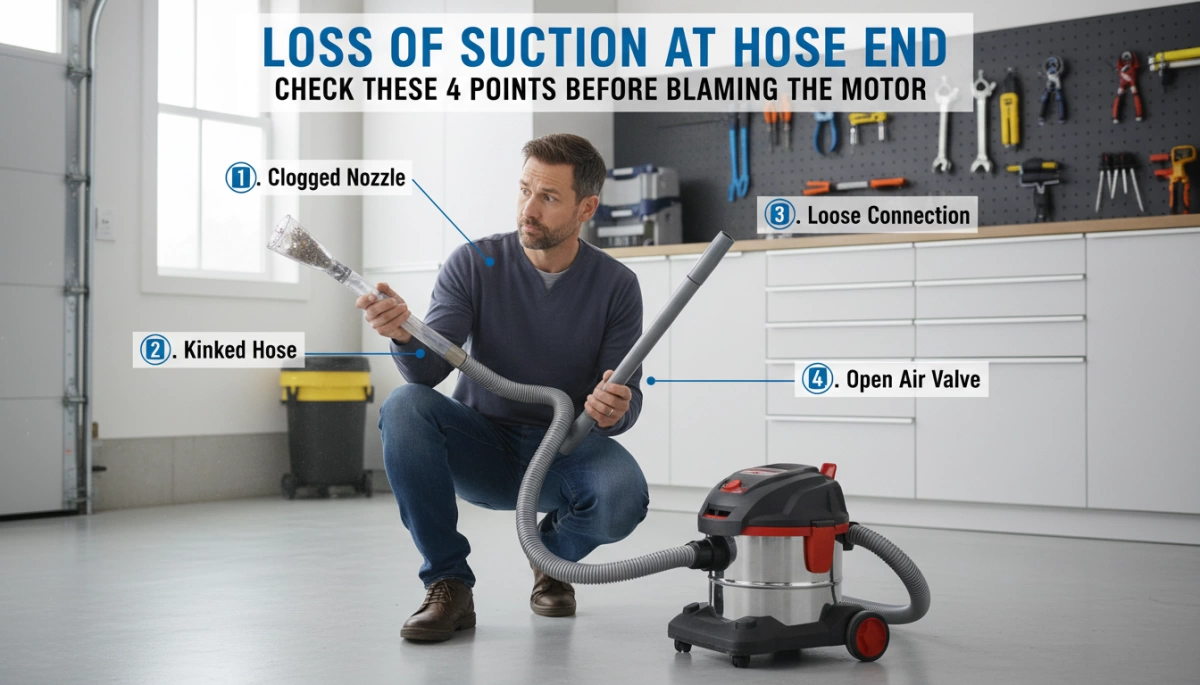

The 4 Key Points to Check for Loss of Suction at Hose End

When you’re facing vacuum hose no suction or weak suction at the hose end, start by checking these four key areas. Most suction problems stem from simple issues here rather than motor failure.

1. Clogs in the Hose or Wand

Blocked hoses or wands are the top reason for vacuum hose clogged issues. To inspect:

- Detach the hose from the vacuum body and attachments.

- Look through it under good light or try the “drop a coin test” – if the coin won’t fall freely, you’ve got a clog.

- Common hidden spots for blockages include bends, cuffs, and wand extensions.

- To remove clogs, use a broom handle or similar tool to push debris through. Compressed air or a flexible grabber tool can also work well.

2. Blockages or Issues at Attachments and Floor Tools

Sometimes the problem is not the hose but the attachments:

- Check the crevice tool, upholstery brush, or turbo head inlets for debris buildup.

- Even when using hose mode, the brush roll can get hair and string wrapped around it, restricting airflow.

- Clear any dirt around the inlet ports where the hose connects to the floor head or wand.

3. Cracks, Leaks, or Loose Connections in the Hose System

Leaks or cracks cause low suction by letting air escape:

- Listen for hissing sounds or notice if the pull feels weaker than usual.

- Inspect the hose closely for splits, holes, or worn cuffs.

- Ensure all connections are tight—check hose-to-body, hose-to-wand, and wand-to-tool links.

- Temporary fixes like tape may help, but for long-term performance, hose replacement is often necessary.

4. Dirty or Clogged Filters Restricting Airflow

Filters clogged with dust or hair reduce suction power at the hose end:

- Both pre-motor and post-motor filters impact airflow.

- Find your vacuum’s filters (consult the manual if needed) and check if they’re full or dirty.

- Wash washable filters and replace disposable ones regularly.

- A clean filter is crucial to fully restore suction; neglecting this often causes performance issues.

For guidance on how to spot and clean your vacuum’s filters, refer to our detailed tips on HEPA and pre-motor filter cleaning.

By systematically checking these four points, you can quickly pinpoint why your vacuum has weak suction at the hose end without rushing to blame the motor.

Quick Diagnostic Test: Isolate the Problem

To figure out where the loss of suction is coming from, start by testing the suction directly at the vacuum body port with the hose removed. This simple step helps narrow down whether the problem lies in the hose or attachments, or if it’s deeper in the motor or filters.

How to test:

- Detach the vacuum hose from the main unit.

- Turn on the vacuum and place your hand over the open port at the vacuum body.

- Check how strong the suction feels.

Interpreting results:

- Strong suction at the body port: This usually means the motor and filters are working fine. The issue likely involves your hose, wand, or vacuum attachments. Common problems here are a clogged vacuum hose, leaks, or blockages in the tools.

- Weak suction at the body port: If you don’t feel strong airflow here, the problem is probably with the filters or motor. Dirty or clogged vacuum filters can greatly reduce airflow, and motor issues might cause poor suction as well.

Running this quick test can save you from wrongly blaming the motor for weak suction at the hose end. Troubleshooting the hose and attachments first usually fixes most vacuum airflow problems. For detailed upkeep tips and how to prevent weak suction, check out our guide on preventive vacuum maintenance.

Additional Common Causes Worth a Quick Check

If you’re still facing loss of suction at the hose end after checking the main issues, don’t forget these additional common causes:

- Overfull dust bin or bag: When the vacuum’s dust container or bag is packed, airflow gets restricted, leading to weak suction at the hose end. Emptying it regularly helps maintain strong pull.

- Height adjustment too high (for upright vacuums): If the vacuum head is set too high off the floor, the brush roll can’t pick up debris efficiently, causing a drop in suction at tools attached via the hose.

- Worn brush roll belt: Even if you primarily use the hose or attachments, a worn or loose brush roll belt can reduce overall airflow and suction power across the vacuum system.

Always include these quick checks in your suction loss troubleshooting routine to save time and avoid unnecessary repairs. For more details on motor-related causes, exploring guides about vacuum motor brush problems can also be helpful.

Prevention and Maintenance Tips

To prevent loss of suction at the hose end and keep your vacuum running smoothly, regular maintenance is key. Here’s what you should do:

- Check the hose and filters regularly: Inspect your vacuum hose for cracks, leaks, or clogs, and clean or replace filters as needed. Dirty or clogged filters seriously reduce suction and airflow, especially at the hose end.

- Empty the dust bin or replace the bag frequently: An overfull bin or bag chokes airflow, leading to weak suction at your tools.

- Store the hose properly: Avoid sharp bends, kinks, or twists when storing the hose. These can cause cracks or breaks over time, resulting in vacuum hose leaks.

- Follow a cleaning schedule based on your vacuum type: Whether you use an upright, canister, or stick vacuum, set reminders to clean attachments, check hoses, and wash or swap filters regularly.

By sticking to these simple routines, you’ll keep your vacuum’s airflow strong and avoid common suction loss issues. For more useful upkeep advice, check out our general tips to extend appliance life that cover similar routine care.

When It’s Actually the Motor (And What to Do Next)

Sometimes, loss of suction at the hose end isn’t just about clogs or leaks. It could be the motor itself. Here’s how to spot it and what to do next:

Warning Signs of Motor Issues

| Symptom | What It Means |

|---|---|

| Burning smell | Motor overheating or wiring problem |

| Unusual grinding noise | Motor bearings or fan damage |

| No suction at vacuum body | Motor or internal airflow failure |

If suction is weak or non-existent directly at the vacuum body port, this often points to motor trouble rather than hose or attachment issues.

Next Steps to Take

- Professional Diagnosis: If you notice these signs, a specialist can inspect your vacuum motor safely.

- Warranty Check: Review your warranty terms before attempting repairs—some motor problems may be covered.

- Replacement Considerations: Motors can sometimes be replaced, but depending on your model and age of the vacuum, it might be more cost-effective to buy a new unit.

For more details on when to seek expert help, check out our guide on when to call a professional for appliance repairs.

Addressing motor issues early can save you from bigger problems—and get your vacuum working at full power again.

FAQ: Common Questions About Loss of Suction at Hose End

Why is there suction at the base but not the hose end?

This usually means the problem lies in the hose or attachments, not the motor. Clogs, leaks, or loose connections along the hose reduce suction at the end while the vacuum body still pulls strongly. Test suction directly at the vacuum body port to confirm if the hose system is the issue.

How do I unclog a vacuum hose without tools?

If you don’t have tools, try these tips: detach the hose and look through it in bright light for blockages; gently shake or tap the hose to dislodge debris; use gravity by lowering one end to let clogs fall out; and peel off the hose cuff to clear any trapped dust at the entry point. However, flexible grabber tools or compressed air often work best to fully remove stubborn clogs.

Can a cracked hose be repaired permanently?

Temporary fixes like duct tape can reduce leaks, but cracks usually need a full hose replacement for a lasting solution. Tape may restore suction briefly, but over time, air will escape, weakening airflow and vacuum efficiency.

How often should I replace vacuum filters?

Filter replacement depends on the vacuum type and usage but generally every 3 to 6 months is recommended. Washable filters should be cleaned regularly and replaced when worn out. Clogged filters lead to poor suction at the hose end, so keeping them clean prevents airflow issues.

Is loss of suction covered under warranty?

Most warranties cover motor and manufacturing defects but not normal wear and tear like clogged hoses, broken attachments, or filters needing replacement. It’s best to check your vacuum’s warranty terms. For motor issues causing complete suction loss, warranty repairs or professional diagnosis may apply. For more on vacuum parts troubleshooting, see our detailed guide on Dyson vacuum repair tips.

This FAQ section helps clarify why vacuum hose no suction issues happen and what simple steps you can take before blaming the motor. Regular maintenance and quick checks save time and keep vacuum performance strong.

Leave a Reply